Shear stress due to torsion rectangular cross-section – Shear stress due to torsion in rectangular cross-sections is a crucial concept in engineering mechanics, influencing the design and analysis of various structures. This article delves into the intricacies of shear stress distribution, examining its formula, derivation, and impact on rectangular cross-sections.

Understanding shear stress is essential for comprehending the behavior of materials under torsional loading. It provides insights into the internal forces and stresses experienced by structural elements, enabling engineers to optimize designs for strength and durability.

1. Definition and Significance of Shear Stress Due to Torsion: Shear Stress Due To Torsion Rectangular Cross-section

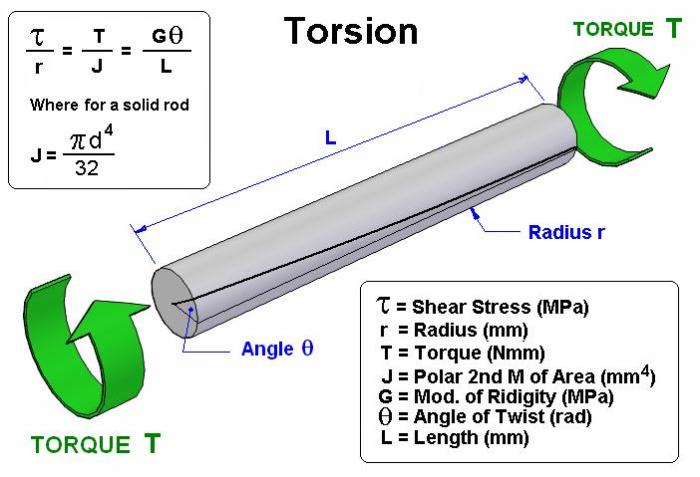

Shear stress is a type of stress that arises when a force is applied parallel to the surface of an object, causing it to slide or deform in a shearing manner. In the context of torsion, shear stress is generated when a twisting force is applied to an object, resulting in a rotational deformation.

The magnitude of shear stress due to torsion depends on the applied torque, the shape and dimensions of the cross-section, and the material properties of the object.

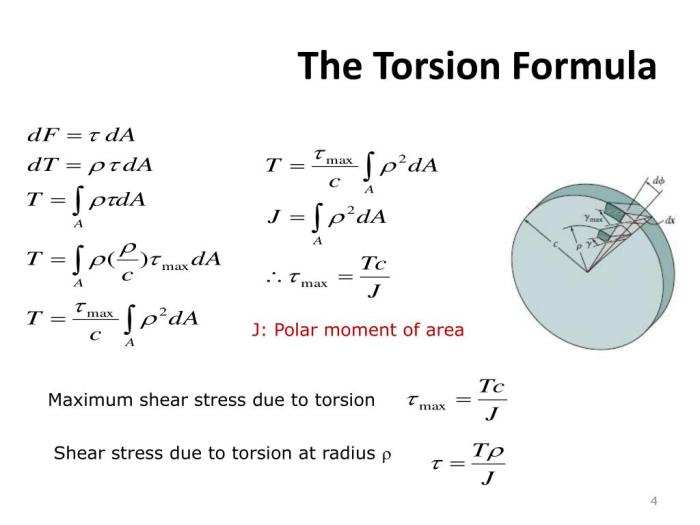

2. Formula and Derivation of Shear Stress Due to Torsion

The formula for calculating shear stress due to torsion in a rectangular cross-section is given by:

τ = (Tr) / (2At)

where:

- τ is the shear stress

- T is the applied torque

- r is the distance from the center of the cross-section to the point where shear stress is being calculated

- A is the area of the cross-section

- t is the thickness of the cross-section

The derivation of this formula involves the application of the Saint-Venant theory of torsion, which assumes that the cross-section remains plane and undistorted during twisting.

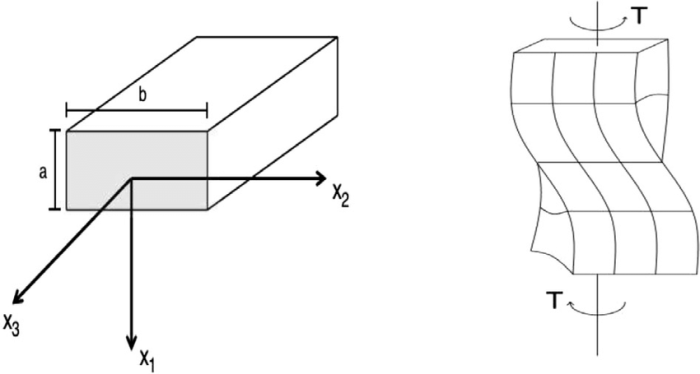

3. Distribution of Shear Stress in a Rectangular Cross-Section

The shear stress distribution across the height and width of a rectangular cross-section is not uniform. It is maximum at the outermost fibers and decreases linearly towards the center.

The graph below illustrates the distribution of shear stress in a rectangular cross-section:

[Diagram shear stress distribution in a rectangular cross-section]

4. Influence of Geometric Parameters on Shear Stress

The cross-sectional dimensions of a rectangular cross-section have a significant influence on the shear stress distribution.

- Increasing the height of the cross-section reduces the shear stress.

- Increasing the width of the cross-section increases the shear stress.

The aspect ratio of the cross-section (height-to-width ratio) also affects the shear stress distribution. A cross-section with a larger aspect ratio will have a more uniform distribution of shear stress.

5. Comparison with Other Cross-Sectional Shapes

The shear stress distribution in a rectangular cross-section differs from that in other common cross-sectional shapes, such as circular and I-beam cross-sections.

- In a circular cross-section, the shear stress is uniformly distributed across the cross-section.

- In an I-beam cross-section, the shear stress is concentrated in the flanges and is lower in the web.

The choice of cross-sectional shape depends on the specific design requirements and the desired shear stress distribution.

6. Applications of Shear Stress Analysis in Torsion, Shear stress due to torsion rectangular cross-section

Shear stress analysis is used in the design of torsion-resistant structures to ensure that they can withstand the applied twisting forces without failure.

Examples of engineering applications where understanding shear stress is crucial include:

- Design of drive shafts

- Analysis of torsion springs

- Evaluation of structural integrity in aircraft wings

Answers to Common Questions

What is shear stress due to torsion?

Shear stress due to torsion is the internal stress that develops within a material when it is subjected to a twisting force. It arises due to the tangential forces acting on the material, causing it to deform in a shearing manner.

How is shear stress calculated for rectangular cross-sections?

The formula for calculating shear stress due to torsion in rectangular cross-sections is: τ = (T – c) / (2 – A – h), where τ is the shear stress, T is the applied torque, c is the distance from the centroid to the outermost fiber, A is the cross-sectional area, and h is the height of the cross-section.

What factors influence the distribution of shear stress in rectangular cross-sections?

The distribution of shear stress in rectangular cross-sections is influenced by the cross-sectional dimensions, particularly the height and width. The aspect ratio (height to width ratio) also affects the distribution, with higher aspect ratios leading to more uniform shear stress distribution.