Consider a cylindrical specimen of a steel alloy, a captivating exploration into the mechanical properties and experimental analysis of this fundamental engineering material. Steel alloys, renowned for their exceptional strength and versatility, exhibit a fascinating interplay of material composition, specimen geometry, and testing methodologies.

This discourse delves into the intricacies of these factors, providing a comprehensive understanding of the behavior and applications of cylindrical steel alloy specimens.

The mechanical properties of steel alloys, such as yield strength, tensile strength, and elongation, are meticulously examined. The influence of alloying elements on these properties is thoroughly discussed, revealing the intricate relationship between chemical composition and material performance. Furthermore, the geometry of the cylindrical specimen is elucidated, highlighting its impact on mechanical behavior.

Mechanical Properties of Steel Alloys

Steel alloys are widely used in engineering applications due to their exceptional mechanical properties. These properties include yield strength, tensile strength, and elongation, which are influenced by the alloying elements present in the steel.

Material Properties

Yield strength is the stress at which a material begins to deform plastically. Tensile strength is the maximum stress a material can withstand before failure. Elongation is the amount of strain a material can undergo before it fails.

Alloying elements can significantly alter the mechanical properties of steel. For example, adding carbon increases the yield strength and tensile strength but decreases the elongation. Adding manganese increases the strength and hardness, while adding nickel increases the toughness.

Specimen Geometry, Consider a cylindrical specimen of a steel alloy

A cylindrical specimen is a commonly used specimen for mechanical testing. It has a uniform cross-sectional area and a length that is typically several times its diameter.

The specimen’s geometry affects its mechanical behavior. The diameter and length of the specimen influence the stress and strain distributions within the specimen, which in turn affect the measured mechanical properties.

Experimental Methods

Various experimental procedures are used to test the mechanical properties of cylindrical specimens. These include tensile testing, compression testing, and fatigue testing.

Tensile testing is the most common method for determining the yield strength, tensile strength, and elongation of a material. In tensile testing, a specimen is subjected to a uniaxial tensile load until it fails.

Data Analysis

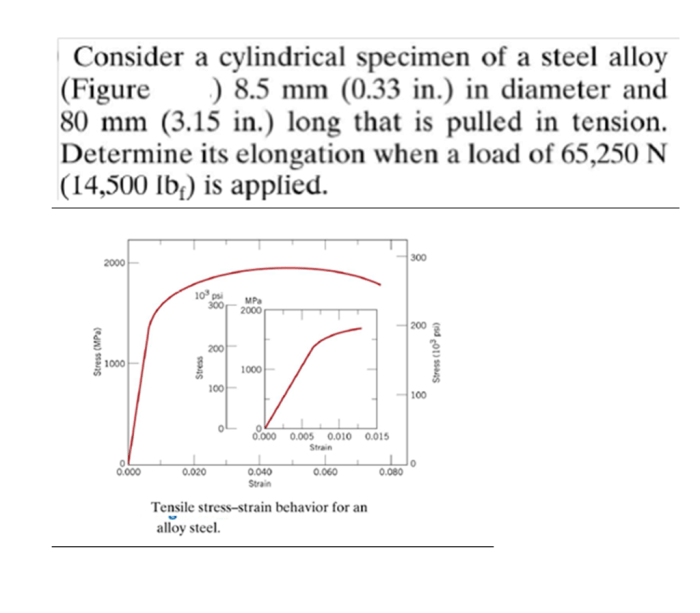

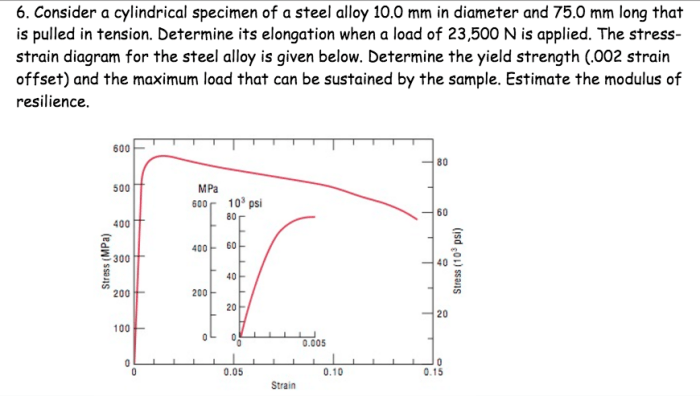

The experimental data obtained from testing a cylindrical specimen is typically analyzed using stress-strain curves. Stress-strain curves plot the stress applied to the specimen against the strain it undergoes.

Different types of stress-strain curves can provide valuable information about the mechanical properties of a material. For example, the yield point on a stress-strain curve indicates the yield strength of the material.

Applications

The mechanical properties of steel alloys are essential in engineering design and analysis. These properties determine the suitability of a material for a particular application.

For example, high-strength steel alloys are used in applications where strength is critical, such as in bridges and buildings. High-toughness steel alloys are used in applications where resistance to fracture is important, such as in automotive parts.

User Queries: Consider A Cylindrical Specimen Of A Steel Alloy

What are the key mechanical properties of steel alloys?

Yield strength, tensile strength, and elongation are the primary mechanical properties of steel alloys.

How does the geometry of a cylindrical specimen affect its mechanical behavior?

The dimensions and shape of a cylindrical specimen influence its stress distribution and deformation patterns, thereby affecting its mechanical behavior.

What experimental methods are used to test the mechanical properties of a cylindrical specimen?

Tensile testing, compression testing, and fatigue testing are commonly used experimental methods for evaluating the mechanical properties of cylindrical specimens.